Air column cushion bag making machine

- Previous: Air Column Box Making Machine

- Next: Air column cushion rolls making Machine

Air column cushion bag production line, Air column cushion bag conversion line, Air column cushion bag production line, Air column cushion bag manufacture line, Air column cushion bag processing line,Air column cushion roll making machine.

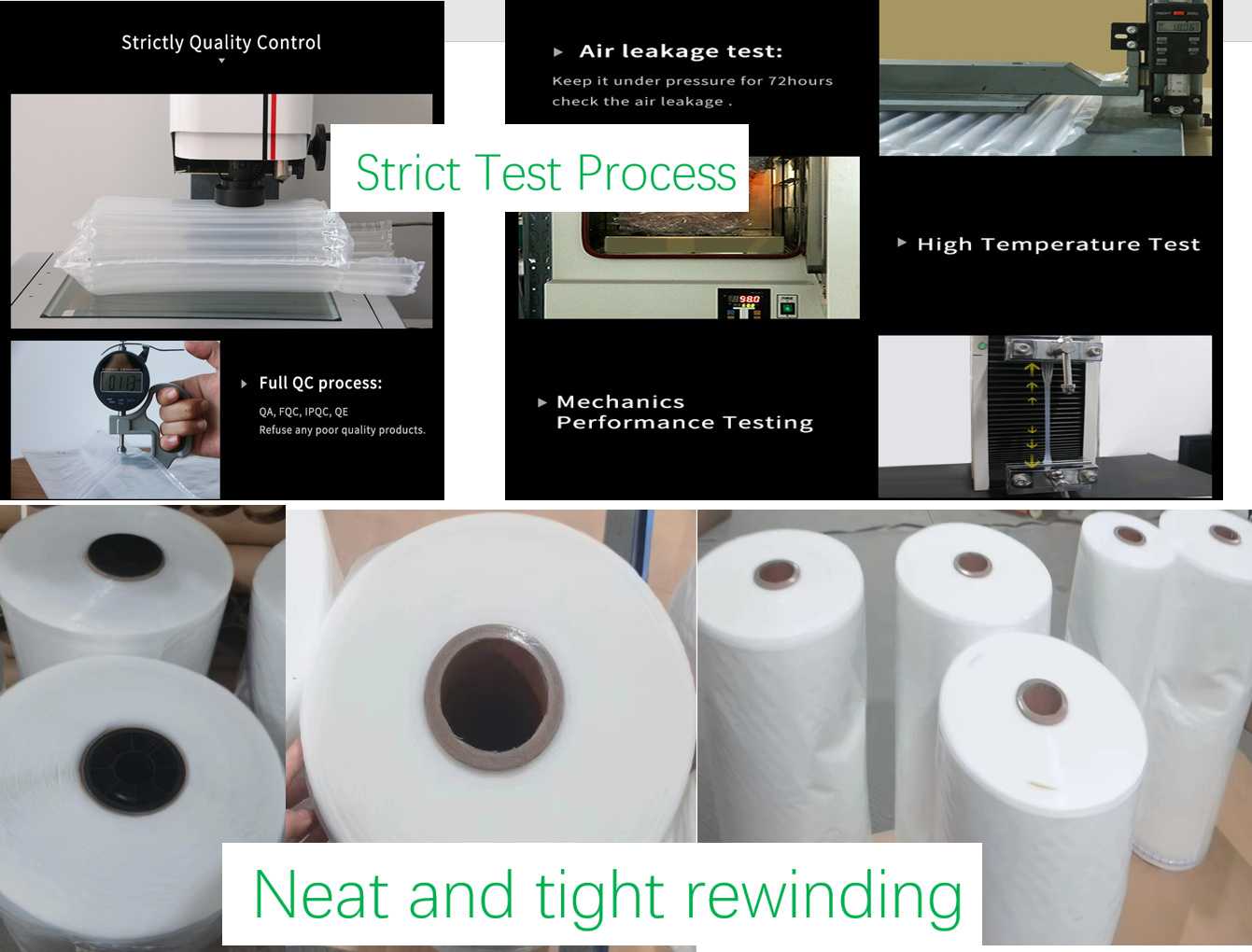

The air column bag making machine is a cutting-edge production line that adopts advanced technology and uses PE co-extruded film to manufacture air bags, cushion bags, filling bags, and paper air bags. These inflatable air column bags are made of LDPE+15%PA (Nylon), which provide excellent shockproof effect after inflation, ensuring the safety of fragile products during transportation. These products are not only low-cost, but also space-saving, easy to recycle, and provide long-term airtightness for storage and transportation. This machine is widely used in the packaging of small household appliances, electronics, logistics and transportation, fragile high-end consumer goods, automotive electronic appliances, precision instruments and other commodities. They can even be applied to the packaging of toner cartridges, ink cartridges, printing consumables, GPS and other computer peripheral equipment, and are ideal fillers for moisture and shock resistance. Our Air Column Cushioned Roll Converting Lines and Air Column Packed Roll Lines offer an excellent way to increase your productivity, reduce labor costs and protect your brand.

Advantages

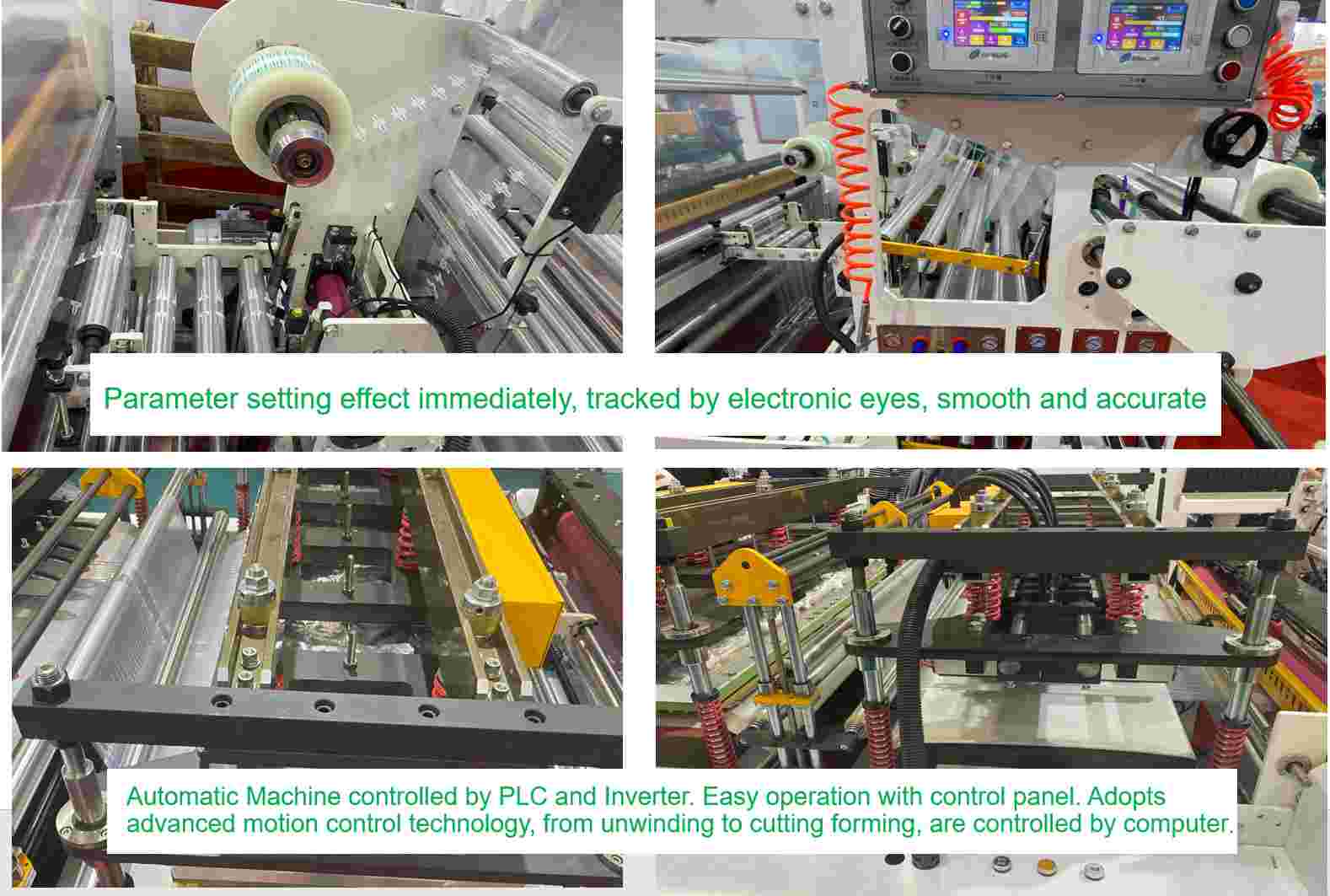

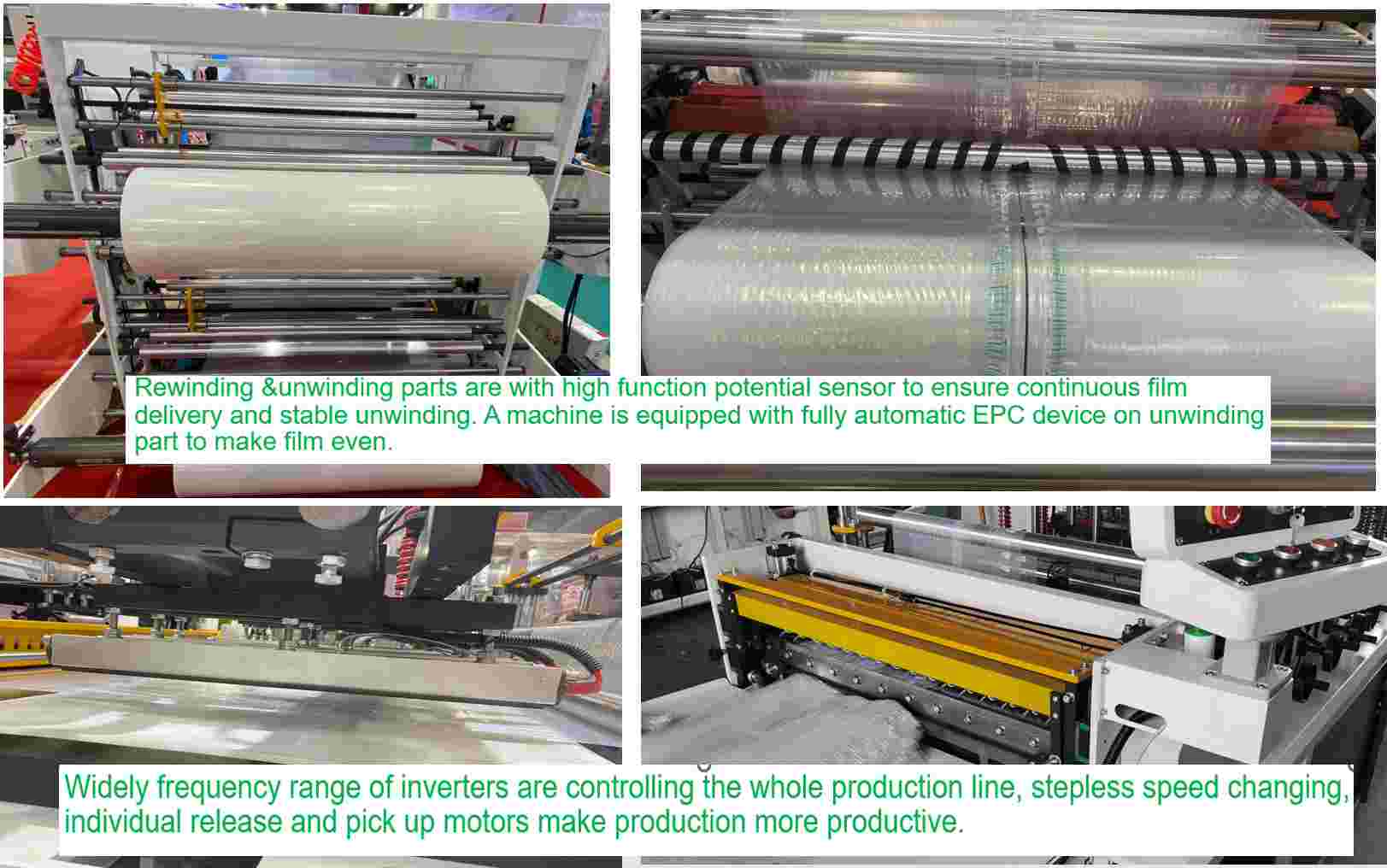

1. Our air column buffer winding roll production line is equipped with a wide range of frequency converters to control the entire production process, which can achieve efficient and smooth speed adjustment. In addition, separate motors for release and pick-up further increase productivity.

2. The take-up and unwinding section is designed with an air-expanding shaft, which is convenient for loading and unloading products, and ensures fast and worry-free replenishment of packaging materials.

3. Both machine A and machine B have the functions of automatic homing, automatic alarm and automatic shutdown, which greatly improves the overall safety and efficiency of the production line.

4. Machine A is equipped with a fully automatic EPC device in the unwinding part to ensure uniform film unwinding.

5. Using high-function potential sensors, our rewinding and unwinding parts ensure continuous film feeding and stable unwinding, ensuring consistent quality of air cushion packaging.

6. Our air column buffer wrapping production and processing line adopts an integrated motor reducer brake design, which eliminates belt chains and noise. This design improves the stability and precision of the production line, thereby improving product quality.

7. The unwinding machine of B machine adopts optical eye EPC to ensure the tension of the film and a safer packaging solution.

8. Our A+B machine combination is optional, but once applied, it will significantly increase the efficiency and output of the production line.

9. Our machine may not be the oldest in the market, but it is the newest model in China. Therefore, it is becoming more and more popular with packaging companies looking to upgrade their air column cushioning bag production lines.

Application& related items

Our Factory