Air column cushion rolls making Machine

Machine Introduction

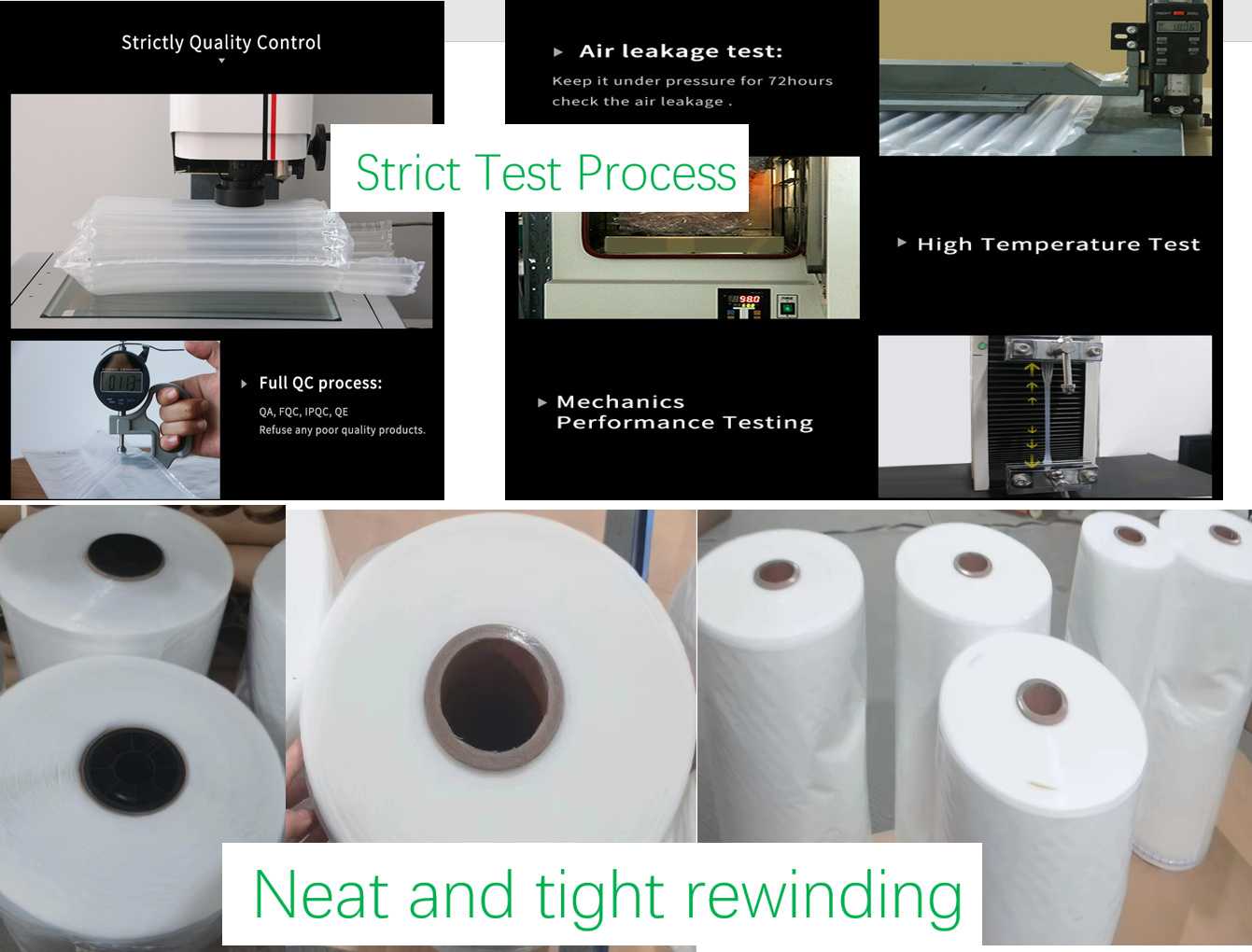

The air column bag making machine is a new production line that uses PE co-extruded film to manufacture various air column bags, cushion bags, filling bags, and paper air bags. The air column bag is inflated with LDPE+15%PA (nylon), which has excellent shock absorption performance and is very suitable for protecting fragile products during transportation without any damage.

Our lines are cost-effective, space-saving and offer many other benefits such as recycling and easy packaging which reduces labor costs while providing good airtight conditions for storage and transport. The air column bag making machine is widely used in the packaging of small household appliances, electronic consumables, logistics and transportation, lamps, fragile high-end consumer goods, automotive electronics and other industries.

In addition, it is a suitable material for electronic product packaging, wine packaging, environmental protection, and cushioning packaging. Our production lines can also act as fillers that play a vital moisture, water and shock resistance role in toner cartridges, lamps, GPS, electronics, printing consumables such as ink and toner cartridges, and other inner packaging needs. With its versatility and adaptability to various packaging materials, it is very suitable for instrumentation and precision instrument packaging products.

Advantages

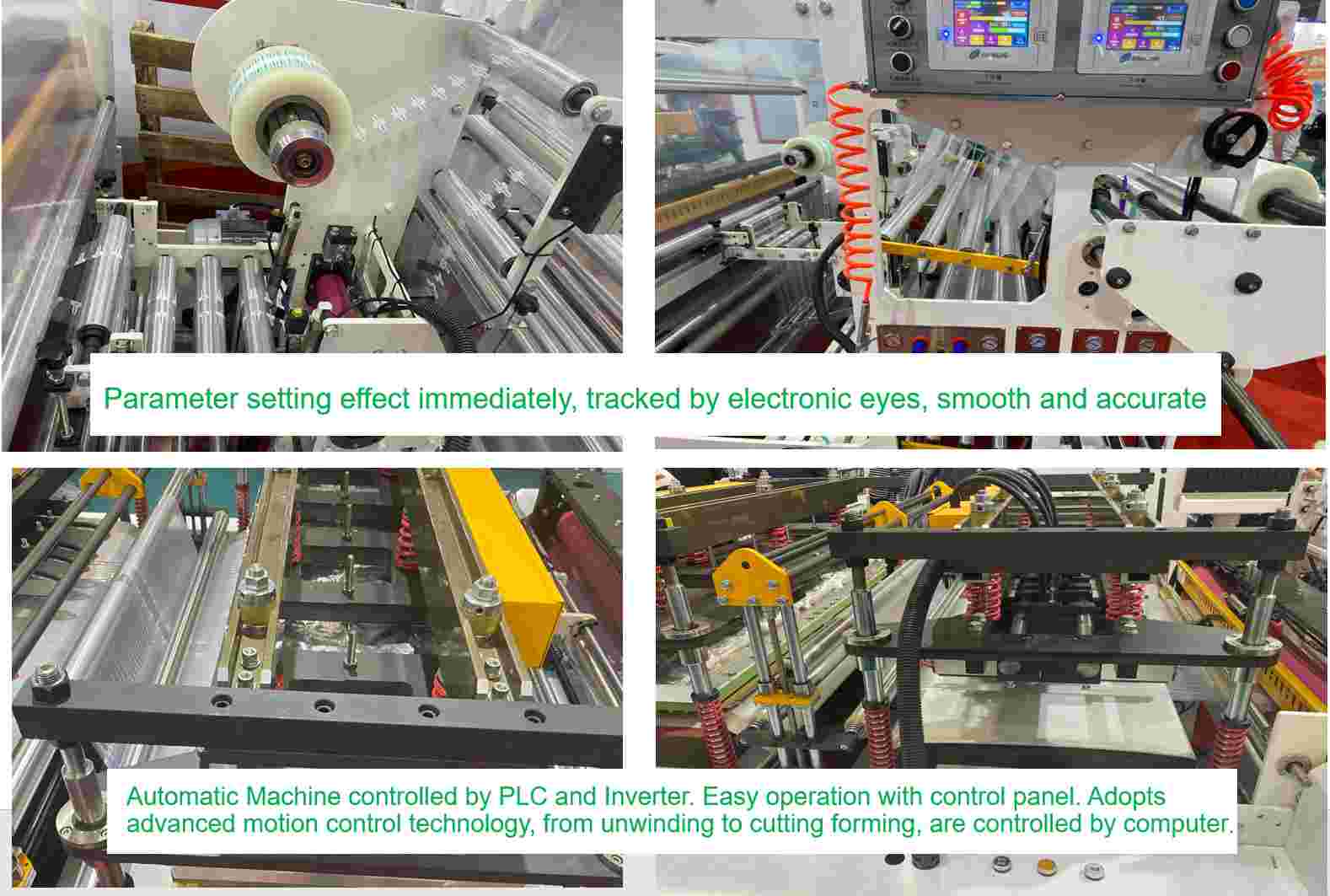

1. Our frequency converter has a wide frequency range, can control the entire production line, and can realize stepless speed change. Separate release and pick-up motors also increase productivity.

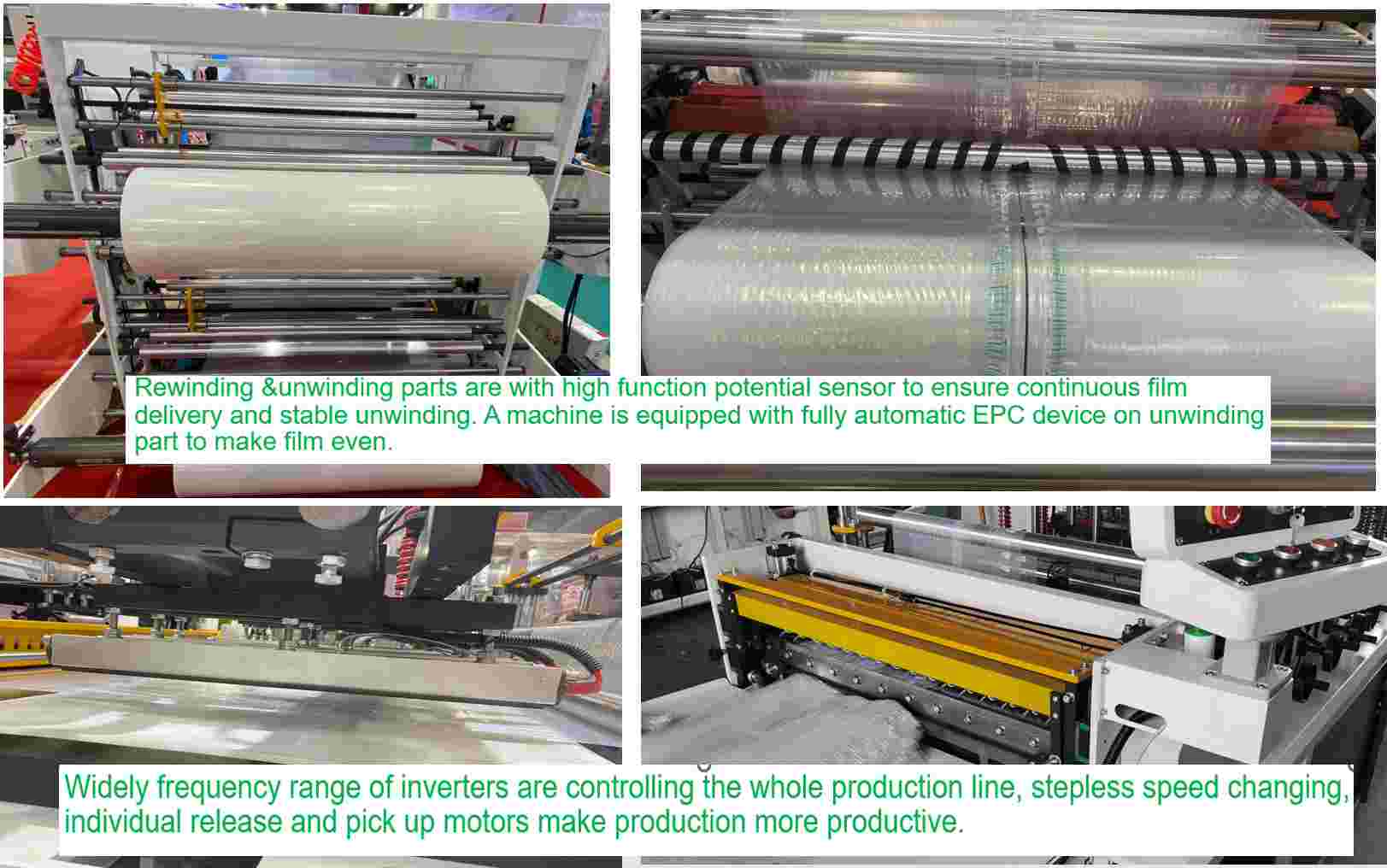

2. Pneumatic shaft is used for unwinding and rewinding, which is convenient for loading and unloading products.

3. Machines A and B have the functions of automatic homing, automatic alarm and automatic shutdown.

4. Machine A is equipped with a fully automatic EPC device in the unwinding part to ensure the flatness of the film.

5. The rewinding and unwinding part adopts a high-function potential sensor to realize continuous film unwinding and stable unwinding.

6. Our main engine integrates the motor, reducer and brake, which has higher stability and precision, without any belt chain and noise.

7. Machine B adopts light eye EPC for unwinding, and unwinds flat and tight film.

8. A+B combination machine can be selected to improve production efficiency.

9. Although it is not the machine with the longest running time in the market, our upgraded models are getting more and more attention from well-known packaging companies, who are upgrading the air column cushion bag production line.

Application

Our Factory