Honeycomb envelope production line

- Previous: Honeycomb envelope making machine

- Next: Honeycomb Mailer Machine

Machin Introduction

Description of Honeycomb envelope production line

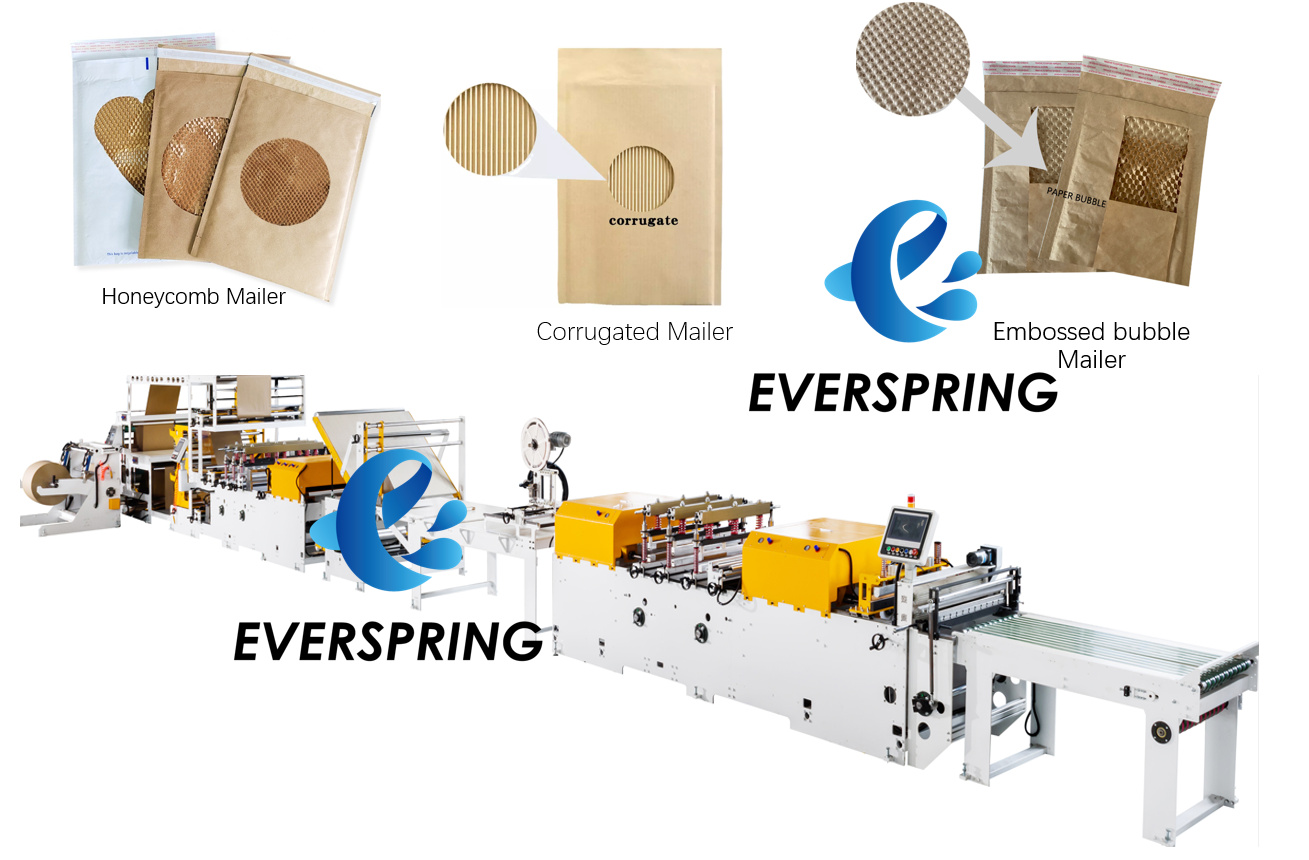

This machine is designed for the production of honeycomb paperboard buffer express bag. It is composed of computer and 12 several servo closed-loop control system, all of them, and the two layers of kraft paper rolling, the honeycomb paper, the pressure on the lining, glue sealing, shear forming, are completed in one production line, The line can make two line smaller sized bags to improve bag making efficiency.

Paper bags produced by Honeycomb Paper Envelope Machine and Paper Bubble Envelope Machine can replace our common plastic bubble film packaging bags, to reduce the white plastics pollution to make our earth greener, cleaner and more livable for our children.

Product Specification

|

Material |

Kraft Paper ,Honeycomb Paper |

|||

|

Unwinding Width |

≦1200 mm |

Unwinding Diameter |

≦1200 mm |

|

|

Speed of Making Bag |

30-50 units /min |

|||

|

Machine Speed |

60 /min |

|||

|

Bag Width |

≦800 mm |

Bag Length |

650 mm |

|

|

Unwinding Part |

Shaftless pneumatic Cone Jacking Device |

|||

|

Voltage of Power Supply |

22V-380V,50HZ |

|||

|

Total Power |

28 KW |

|||

|

Machine Weight |

15.6 T |

|||

|

Appearance Color of Machine |

White Plus Gray&Yellow |

|||

|

Machine Dimension |

31000mm*2200mm*2250mm |

|||

|

14 mm thick Steel Slates for The Whole Machine (The machine is plastic sprayed.) |

||||

|

Air Supply |

Auxiliary Device |

|||

Our Factory

Xiamen Everspring Technology Co.,Ltd is committed to the development and production of environmental-friendly protective packaging equipment, who focuses on providing one-stop solutions in protective packaging equipments and Eco-friendly materials to customers worldwide.

Our products include: Honeycomb envelope mailer processing production line, Honeycomb rolls cutting making machine, Kraft paper fan folding machine, Air column cushion rolls making production line, Air cushion film rolls making conversion line etc.

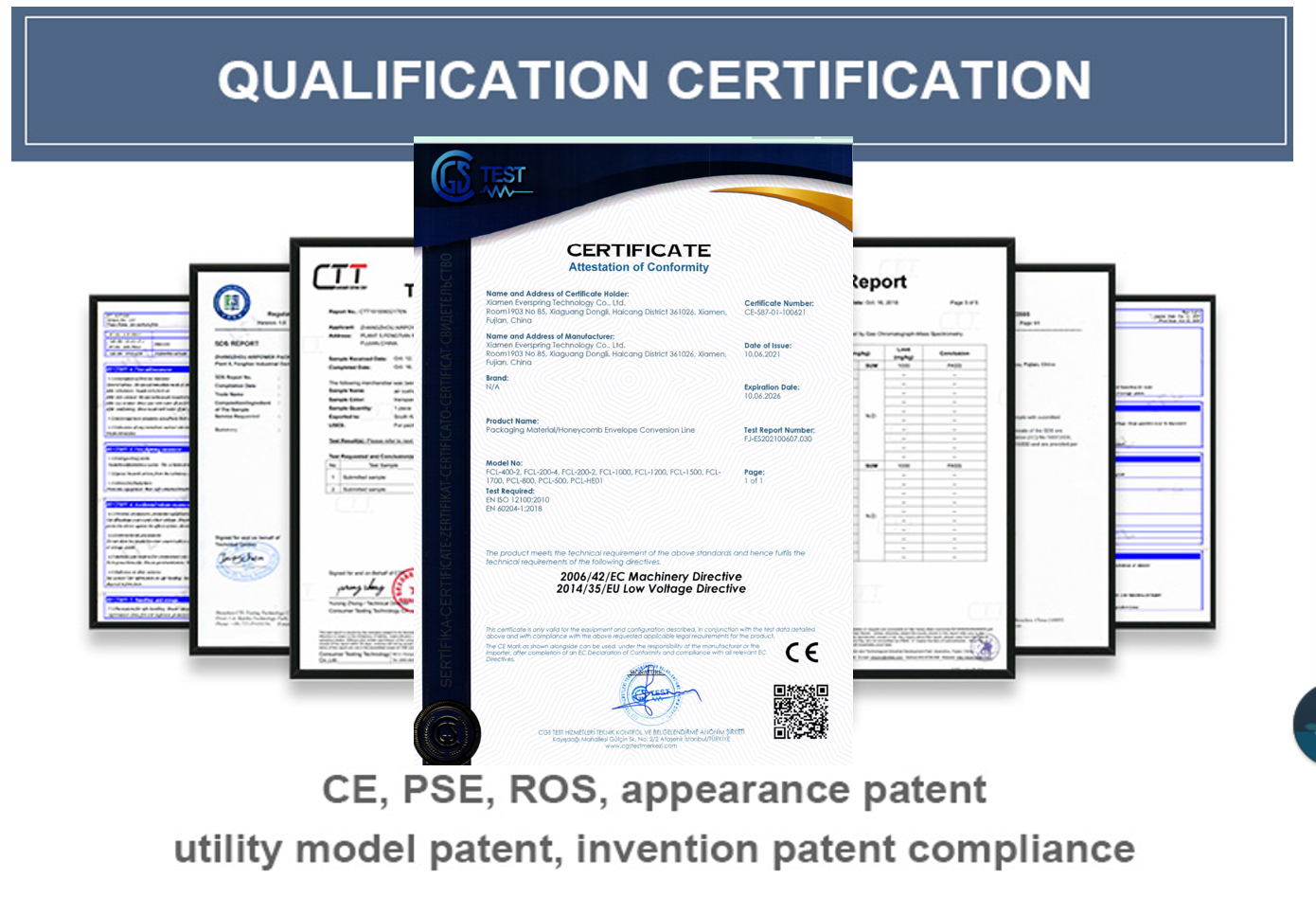

Certifications