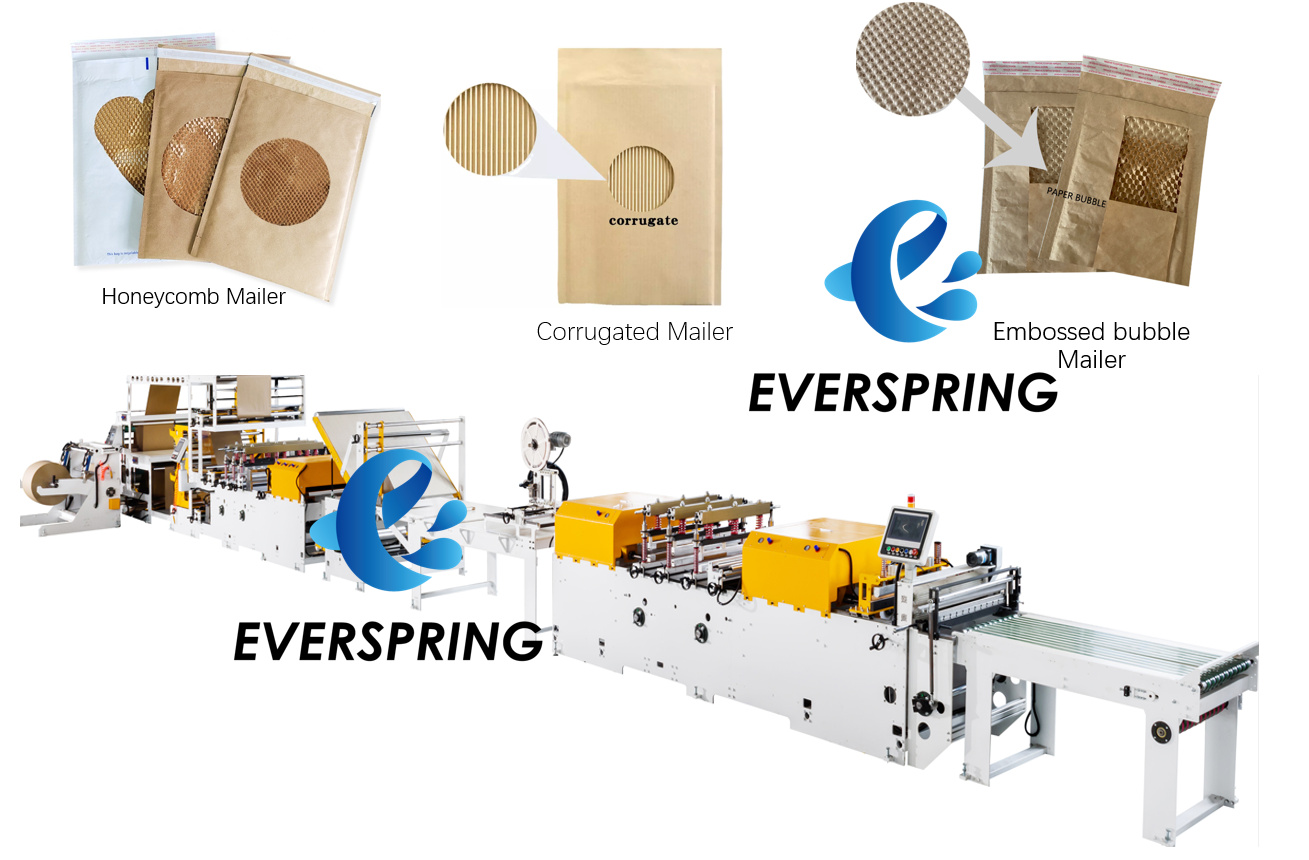

Honeycomb mailer envelope conversion line manufacturer

Machin Introduction

Summary of Hexcel wrap padded mailer making machine

1. Hexcelwrap padded mailing bag making machine is specially designed to produce mailing bags by combining kraft paper with in-line air bubble paper, honeycomb paper or corrugated paper using water and hot hot glue.

2. The bag making process is to insert three rolls of kraft paper into the release frame, and the middle layer is sandwiched between two layers to press air bubble paper, honeycomb paper or corrugated paper, and fix it in place with some spray glue. Add secondary horizontal spray glue after vertical and horizontal lamination. Then the paper is folded, heat-pressed and sealed, and cut into an environmentally friendly cushioning bag suitable for express delivery.

3. This machine adopts advanced motion control technology, which can realize computer-controlled unwinding, cutting and forming of paper bags. The produced bags are flat, environmentally friendly, and sealed firmly and reliably. The machine is easy to operate and is an excellent choice for making high quality bags.

4. This machine can also produce honeycomb mailing bags, corrugated paper mailing bags, embossed paper bubble mailing bags.

Product Specification

Technical Parameters of Hexcelwrap padded mailer making machine

|

Model: |

EVSHP-800 |

|||

|

Material: |

Kraft Paper, Honeycomb paper |

|||

|

Unwinding Width |

≦1200 mm |

Unwinding Diameter |

≦1200 mm |

|

|

Speed of Making Bag |

30-50 units /min |

|||

|

Machine Speed |

60 /min |

|||

|

Bag Width |

≦800 mm |

Bag Length |

650 mm |

|

|

Unwinding Part |

Shaftless pneumatic Cone Jacking Device |

|||

|

Voltage of Power Supply |

22V-380V,50HZ |

|||

|

Total Power |

28 KW |

|||

|

Machine Weight |

15.6 T |

|||

|

Appearance Color of Machine |

White Plus Gray&Yellow |

|||

|

Machine Dimension |

31000mm*2200mm*2250mm |

|||

|

14 mm thick Steel Slates for The Whole Machine (The machine is plastic sprayed.) |

||||

|

Air Supply |

Auxiliary Device |

|||

Our Factory