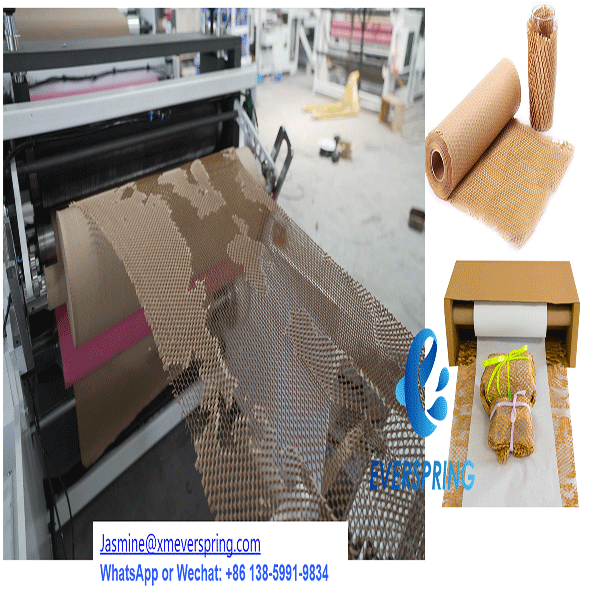

Honeycomb wrap cushion rolls making machine

- Previous: Honeycomb paper making machine

- Next: Honeycomb Wrap Roll Making Machine

Machine introduction of Honeycomb Paper Kraft Buffer Paper Making Machine

This Protective Honeycomb Paper Roll Forming Machine is used for cutting and rewinding kraft paper roll into honeycomb rolls.

It is light in weight, small size, low noise. Also with high efficiency and energy saving. Fast dynamic response and stable running speed are the significant advantages.

This Honeycomb paper converting line adopts frequency conversion speed regulation, fully integrated circuit control. Complete functions, good repeatability, stable speed. Reliable work. Absolutely correct movement. Winding and unwinding tension is automatically controlled. Two sections of electronic meter to ensure the accuracy.

Features of Honeycomb paper roll manufacturing line:

DURABLE CUTTER SHAFT:

The main roller cutter can last 6 month

Make about 2millon meter honeycomb paper before maintenance.

Save maintenance cost for you.

FULLY AUTOMATIC:

Unwinding adopts air expansion shaft for loading, 10kg brake automatic tension (50kg), hydraulic automatic feeding (feeding weight 1.5 tons and diameter 1200mm);

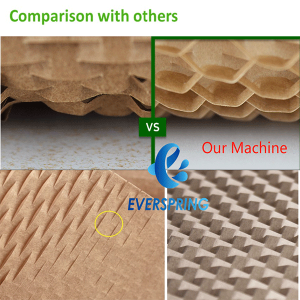

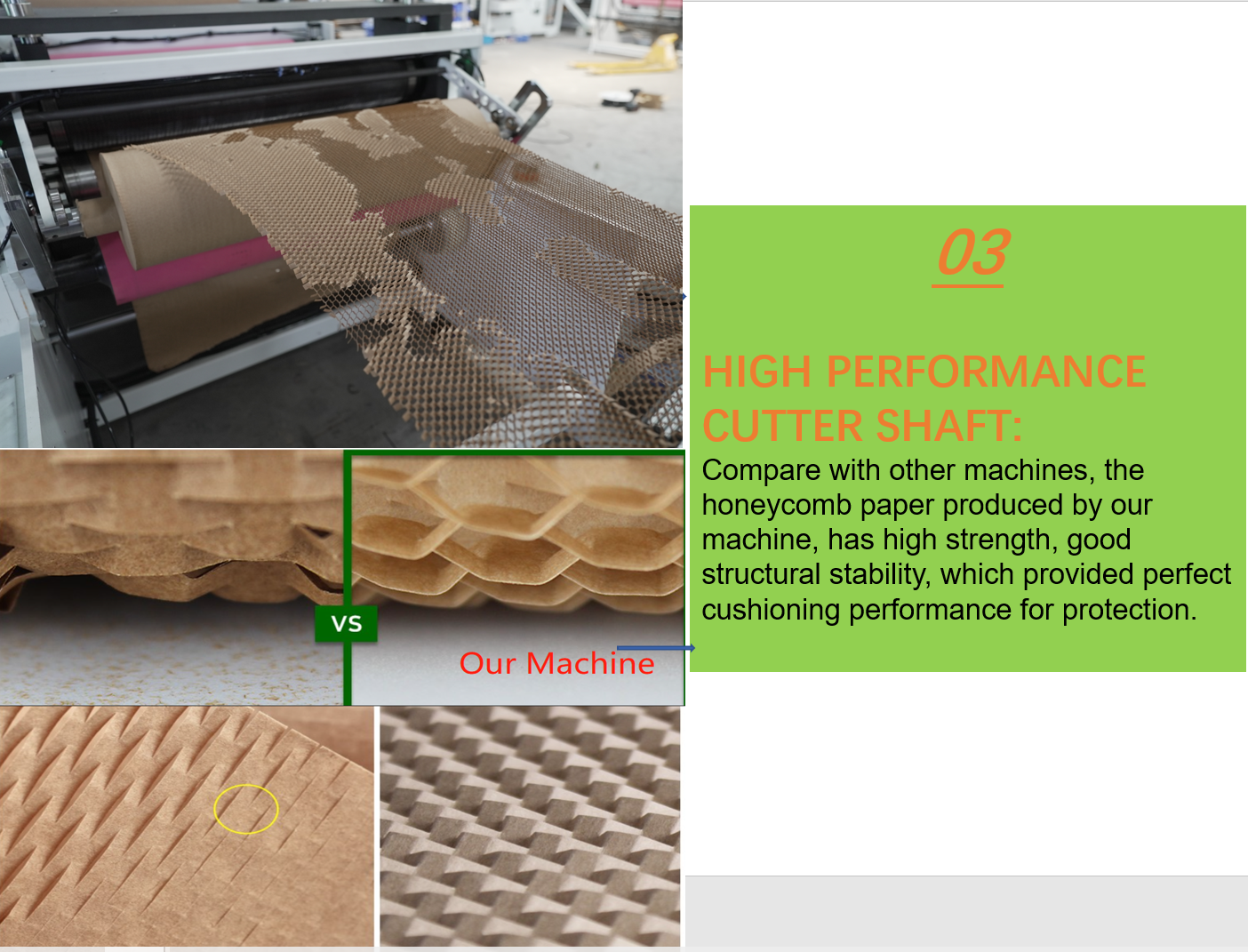

HIGH PERFORMANCE CUTTER SHAFT:

Compare with other machines, the honeycomb paper produced by our machine, has high strength, good structural stability, which provided perfect cushioning performance for protection.

NEAT AND TIGHT REWINDING:

Compare with other machines, the honeycomb rolls produced by our machine is quite neat and tight, no wrinkles after stretching, provide you excellent cushioning.

Application& related items

Our Factory